Knowledge popularization:

The full name of TPE is ‘thermoplastic elastomer’, which is the abbreviation of Thermoplasticrubber. It is a kind of elastomer that has the elasticity of rubber at room temperature and can be plasticized at high temperature. The structural feature of thermoplastic elastomers is that different resin segments and rubber segments are composed of chemical bonds. The resin segment forms physical cross-linking points by virtue of interchain force, and the rubber segment is a highly elastic segment that contributes to elasticity. The physical crosslinking of the plastic segments is reversible with temperature, showing the plastic processing properties of thermoplastic elastomers. Therefore, thermoplastic elastomer has the physical and mechanical properties of vulcanized rubber and the processing properties of thermoplastics. It is a new type of polymer material between rubber and resin, and is often referred to as the third-generation rubber.

Thermoplastic elastomers have the following characteristics in processing applications:

1. It can be processed and formed by standard thermoplastic processing equipment and processes, such as extrusion, injection, blow molding, etc.

2. Without vulcanization, it can prepare and produce rubber products, reduce vulcanization process, save investment, low energy consumption, simple process, shorten processing cycle, improve production efficiency and low processing cost.

3. The corner waste can be recycled, which saves resources and is also beneficial to environmental protection.

4. Since it is easy to soften at high temperature, the use temperature of the product is limited.

Advantage:

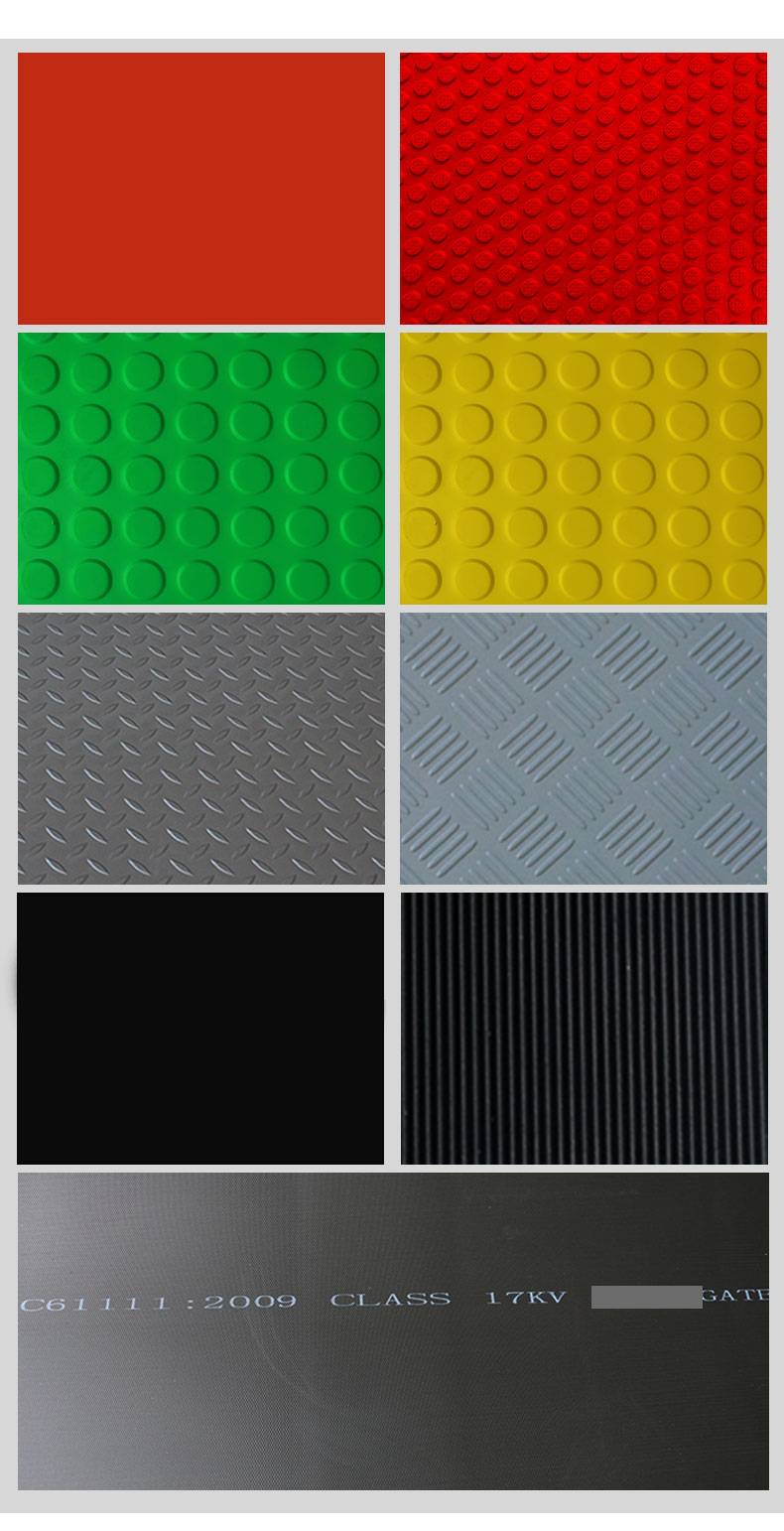

It has the advantages of non-toxic environmental protection, consistent color, oil resistance, anti-aging, waterproof, wear-resistant, beautiful, etc., and TPE has high insulation, can reach high voltage 50KV without breakdown, and truly achieve high-performance insulation board. It can also be sprayed, and 90% of the existing customers have converted from plastic sheets to TPE to make insulation boards.

Shortcoming:

The heat resistance of TPE is not as good as that of rubber. As the temperature rises, the physical properties decrease greatly, so the scope of application is limited. Please pay attention to the operating temperature, and TPE is not suitable for gaskets, gaskets, seals, etc. with specific properties.

Post time: Apr-07-2022